Fast becoming market leaders in quality and innovation

At PRF, we are passionate about innovative product development, with an emphasis on helping customers reduce manufacturing time, and improve efficiency and cost-effectiveness.

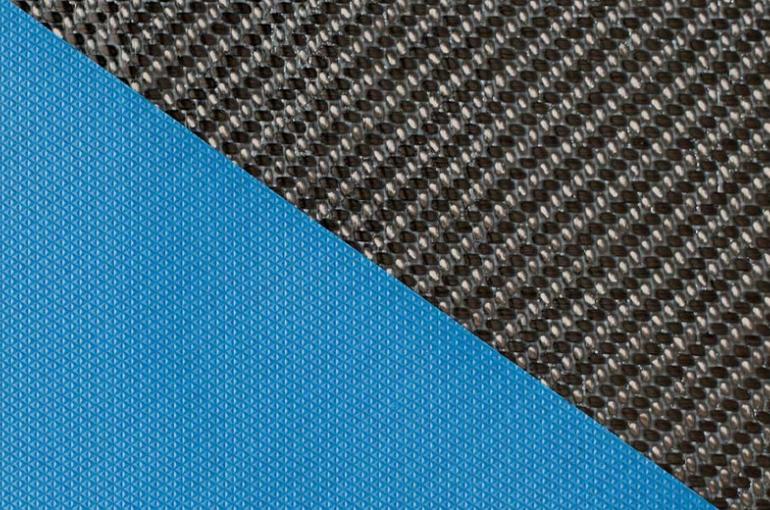

- Innovative range of prepreg systems, designed to suit your manufacturing needs

- Visual quality, toughened, low temperature, snap cure, unidirectional, tooling and more

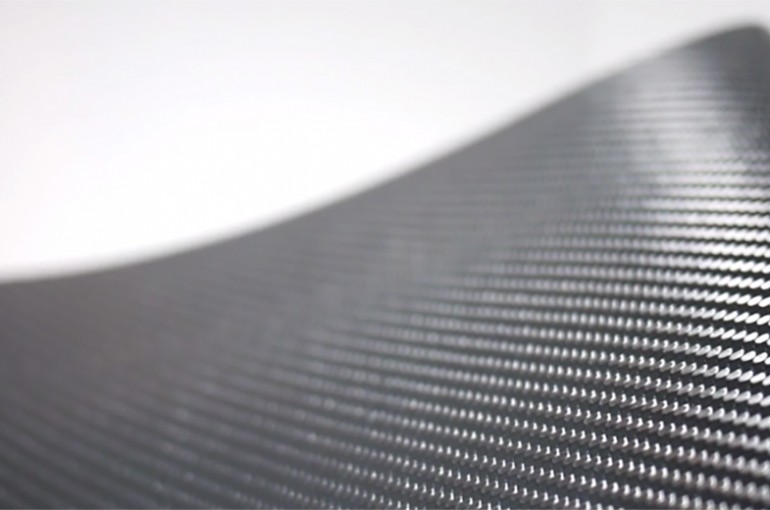

- A wide range of fabric options, supported by 40 years’ experience working with technical textiles

- Great customer feedback received on the quality of materials, handling and finish in both tools and components

- Short lead times – from our manufacturing line to you in 2–3 weeks, for standard materials

Review our full range in our prepreg selector guide here.

Highlights from our range:

› RP442 Low temperature prepreg with a longer out life.

› RP542-1 Mid-temperature component prepreg with superb surface finish.

› RP542-4 Intermediately toughened system for woven and unidirectional materials.

› RP549 Highly toughened prepreg with a Tg of 214°C (DMA) and excellent mechanical properties.

› RP570 eXpress cure A true snap cure prepreg, with a complete processing time of 4 minutes.

› RP570 FR eXpress cure Formulated for structural components requiring FST properties, RP570 FR is cured and demouldable after 5 minutes at 160°C.

› RP800 Tooling prepreg From our class-leading range of prepreg systems, providing excellent quality with an 8 hour cure at 50°C.

Read more about our component and tooling systems and find out more about our prepreg manufacturing and in-house resin system development, R&D and lab facilities.