At PRF, quality and innovation are at the forefront of everything we do.

Our process laboratory is used to test how our materials process. Equipped with presses, test ovens and facilities for hand lay up and vacuum infusion, our team works here on testing material processing to ensure that our materials process to our customers' requirements, with a focus on making processing cost-effective and improving efficiency.

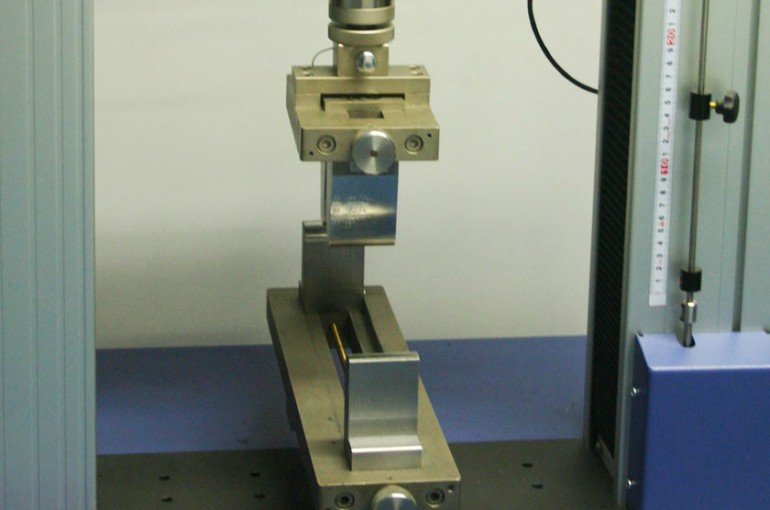

We also have a mechanical testing laboratory, where we perform mechanical testing (bending, tensile, shear and peel off) to ISO and ASTM standards, as well as rheology, DMA and DSC. Across 2020 and 2021 we invested heavily in our R&D capabilities, extending and upgrading our testing equipment and improving our capabilities across the board.

Product development is central to our mission at PRF. Since 1982, we have been at the forefront of innovation and product development, firstly with technical textiles and now with our prepreg manufacturing. Our product developments are driven by customer requirements and also with a view to offer new and improved systems with 21st century resin technologies. For our customers, we are focussed on developing new prepreg systems with provide better technical outcomes and/or offer improved manufacturing processes; creating components of a higher quality, faster and in a more cost-effective manner.

With our unique history and experience supplying a full range of composite materials, we also look at innovation across our full product range, looking at how and where we can support our customers in their quest for high quality but also cost-effective components.

Follow us on LinkedIn to stay up to date with our latest announcements and product developments.